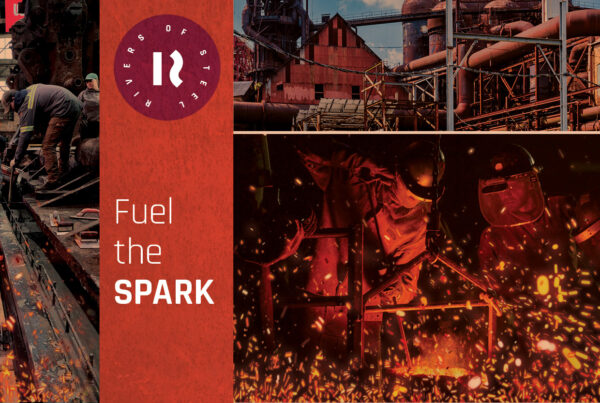

Malayna Arambula, now an employee of Rivers of Steel, first joined the organization through a pilot workforce development program.

Partners for Creative Economy: Workforce Development

Partners for Creative Economy is an economic development initiative of Rivers of Steel that combines five strategies for uniting, uplifting, and empowering communities throughout the Rivers of Steel National Heritage Area. Long-standing efforts, such as the Mini Grant program and community partnerships, have been expanded and paired with newer enterprises, including the Creative Leadership Program and the forthcoming Center for Heritage Tourism. This article is the first in a series that explores each of these key elements; it focuses on new workforce development initiatives recently launched by Rivers of Steel.

By Lynne Squilla, Contributing Writer

Why Workforce Development

In its more than thirty-year history, Rivers of Steel has been devoted to preserving the region’s industrial and cultural heritage, including its labor history. In saving some of the last remaining physical artifacts of iron and steelmaking in the area, Rivers of Steel is also rekindling labor skills that were fast disappearing, training a new workforce who will be able to contribute to historic preservation projects or apply their knowledge to more conventional industries.

This focus on workforce development is one pillar of Rivers of Steel’s ambitious Partners for Creative Economy, an initiative that works in collaboration with heritage and cultural organizations and municipalities in the eight southwestern Pennsylvania counties that compose the Rivers of Steel National Heritage Area: Allegheny, Armstrong, Beaver, Butler, Fayette, Greene, Washington, and Westmoreland. The goal is to strengthen and uplift communities that were hard-hit by and are still struggling to recover from the collapse of Big Steel and related industries in the 1980s, using preservation efforts, creative placemaking, and tourism, along with funding and other community development support.

“These historical assets offer unique opportunities to train local individuals in hands-on traditional trades like welding, masonry and blacksmithing—through projects that help preserve an important piece of their own history,” explains Chris McGinnis, Rivers of Steel’s senior director of programs and regional partnerships. “In the ’80s, these industrial relics were like an open wound—a fresh reminder of the jobs that no longer existed. In the intervening years, resulting from the work of Rivers of Steel, many people now recognize the value of these assets.”

He continues: “These remnants of industrial life were saved, but a vision was needed to encourage people to come back to the area. In order to support tourism and revitalize these communities, our efforts in redeveloping these landmarks were—and still remain—targeted at helping local communities and former steelworkers weather the lean years after the collapse of Big Steel. In the process, we created a destination that shares stories essential to understanding the heritage and legacy of southwestern Pennsylvania.”

An Industrial Tour of the Carrie Blast Furnaces

The Epicenter of American Heavy Industry

A walk around the Carrie Blast Furnaces National Historic Landmark site offers a scaled-down reminder of the massive network of mills and factories that lined the entire Monongahela Valley for more than a century, virtually all of them now gone. The greater Carrie site itself occupied 107 acres along the river, which was part of the U.S. Steel Homestead Works, which employed more than 15,000 people. Blast Furnaces #6 and #7 at Carrie were rescued from demolition, along with an array of infrastructure, including the AC Power House and Blowing Engine House. In its prime, six furnaces at Carrie churned out 9,000 tons of iron daily.

Workers at the Homestead Works possessed highly specialized skills and had colorful job titles such as batch pickler, pig machine operator, scarfer, larryman, babbitman, skull cracker craneman, and the more obvious stove tender, salt thrower, cinderman, and car dumper operator. Millwrights also possessed a variety of general talents, too, for welding, machining, engineering, carpentry, and bricklaying—all required for maintaining the furnaces and mills.

The workforce development program will focus on the skills a millwright would need—and the more specialized skill set on how to preserve and restore industrial artifacts and infrastructure. While there is a need to develop expertise in the manual trades in general, this program will help establish industry standards for what is required when addressing historic, industrial preservation projects.

Rick Rowlands and Adam Taylor, who help to train apprentices, burn off old grease on the crankshaft of the 48-Inch Universal Plate Mill.

Developing a Specialized Workforce

Rivers of Steel hopes to remedy this talent vacuum by recruiting and educating a new workforce in the region who will be capable of performing specialized skills that not only support Rivers of Steel’s own preservation efforts, but also those in other regions of the country.

The first project of Rivers of Steel’s workforce development effort is the historic preservation of the 48-Inch Universal Plate Mill on the Carrie site. The last mill of its kind in the world, it currently sits in pieces, waiting to be restored and rebuilt inside the Blowing Engine House, ultimately forming the centerpiece of Carrie’s future visitors center, museum, and archives.

A pilot program in the summer of 2023, funded by the Department of Conservation and National Resources, allowed Rivers of Steel to train two apprentices, Malayna Arambula and Derek Stein, to begin learning about the work of historic preservation from the ground up, explains project manager Rick Rowlands.

“They started with cleaning ten tons worth of dirt, grease, and grime off the parts,” he laughs.

As the project transitions into full restoration, with support from an Appalachian Regional Commission POWER grant and a Save America’s Treasures grant from the Institute of Museum and Library Services, among other sources, these apprentices are being immersed in more specific experiences. Says Rowlands, “They’ll get to do a bit of everything: metalworking, welding, some machining, learning about rigging and lifting—even some concrete work. The best way of learning is to have to do a little of everything.”

Mentoring workers in this way echoes the kind of apprenticeship that went on in the mills and factories along the Mon River for decades. “We’re recreating what was commonplace in the Mon Valley,” Rowlands explains. “It’s kind of something that’s not done anymore.”

The 48-Inch Mill project is just the first of many projects to come. Skills taught through the program will include traditional masonry, welding (ARC & MIG), foundry work and pattern making, blacksmithing, basic carpentry, basic structural engineering, metal fabrication, and more. Participants, made up of youth and adults from the region, will actively assist on Rivers of Steel’s preservation projects as well as on test models, learning valuable decision-making and problem-solving competencies. Graduates from the program may continue working with Rivers of Steel as paid staff when positions are open or take their experience to other organizations in need of this valuable knowledge.

Creating Opportunities

In many ways, the work of this new labor force will be as specialized as that of the millworkers who came before them. These trainees will work on and around sensitive surface areas that have been exposed to the elements and require highly specialized techniques and handling. They will learn to restore historic masonry and do structural welding, as well as perform artisanal blacksmithing and foundry work. Rivers of Steel’s historic landmark sites are a vast classroom for honing these critical skills.

Samantha Swartz, the director of the historic preservation workforce training program.

“Having this workforce development piece lets Rivers of Steel use restoration and preservation as a springboard for this exclusive training of talent,” adds Ron Baraff, Rivers of Steel’s director of historic resources and facilities. “The next Save America’s Treasures grant is for the Blowing Engine House, to restore and stabilize that building, which requires many facets of skills. This will all become training grounds for work skills that can be used here and at other historical sites and workplaces.”

Samantha Swartz is the new director of the historic preservation workforce training program and is excited for the challenges ahead. “One of the great things about workforce development at Carrie is it is full circle. It is a site where opportunity was lost, and now it’s a footprint for opportunity for the whole Mon Valley. It’s pretty incredible—the potential for these efforts!”

An Early Foray into Workforce Development

Years before the workforce development initiative became a formal part of Rivers of Steel’s vision and mission, the organization used its historic sites to retrain area workers. One of the earliest efforts was at the Bost Building National Historic Landmark—a building recognized for its connection to the tragic 1892 Battle of Homestead and the subsequent lockout and strike.

Rivers of Steel’s President and CEO Augie Carlino, an advocate in the initial community-based efforts to save the Carrie Furnaces in Swissvale, along with the Bost Building in Homestead, and the Pump House and Water Tower in Munhall, describes an early workforce development effort following the massive mill shutdowns:

“A federal economic development grant in the late 1990s was Rivers of Steel’s first workforce development project at the Bost Building,” Carlino explains. “We trained mostly former, displaced, and some retired steelworkers as tour guides. They had the stories and the experiences; they just needed some guidance in how to be docents to interpret those stories for visitors. The intent was—and still is—to get into these communities that have been left behind and employ people—to get them interested and invested in these new means of economic identity and opportunity.”

Michael P. McCauley, Jr., Rivers of Steel’s maintenance manager, who is also a millwright, is part of this growing workforce.

Contributing to the New Economy

Augie Carlino points out how all of these places fit Rivers of Steel’s mission and vision. “Philosophically—the Bost Building, Pump House, Carrie—these preservation projects we see as beyond ‘save and sit.’ Preservation is not static. They are symbols of who we were—and are—contributing to a new economy in the area. The workforce, along with tours, events, and demonstrations, contributes in new and different ways to these communities and economies,” explains Carlino.

Chris McGinnis agrees. “Carrie and similar sites can be just passive places to enjoy, or it can be much more impactful when the community gets to take part in restoring, interpreting, and keeping these places alive.”

Summing up the workforce development initiative, Samantha Swartz notes, “I am a history nerd, and I most love the history of the working person. When you discover the history of Carrie, you are walking on truly historic land where lives were lost and futures destroyed. You can sense it! But I also sense the phoenix coming up out of the ashes and giving back to the community, bringing hope for the region.”

In 2009, former Homestead steelworker and grievance man-turned-songwriter Mike Stout wrote a lyric celebrating Pittsburgh’s glorious industrial history. It touches on what inspires Rivers of Steel’s workforce development program:

“To the millions who worked in your factories and mills,

The ghosts of their labor are living there still.”

Rivers of Steel’s vision embraces the powerful lingering spirit of ingenuity and hard work that built not just this region, but the entire nation. In restoring and preserving the physical remains of the once-mighty iron and steel industry, Rivers of Steel is able to preserve and promote marketable skills and grow a small but knowledgeable labor force in the region who will be dedicated to carrying on the task of saving priceless industrial artifacts for future generations and visitors near and far.

Lynne Squilla is a skilled and creative storyteller. She honed her craft as a writer and producer / director of original scripts, documentaries, articles, web content, stage, and other live presentations. While her work has taken her across the globe, she’s rooted in the Mt. Washington neighborhood of Pittsburgh, and has a passion for sharing stories about our region’s past.

Check out Lynne’s previous article on the Historic Preservation of the 48-Inch Universal Plate Mill.