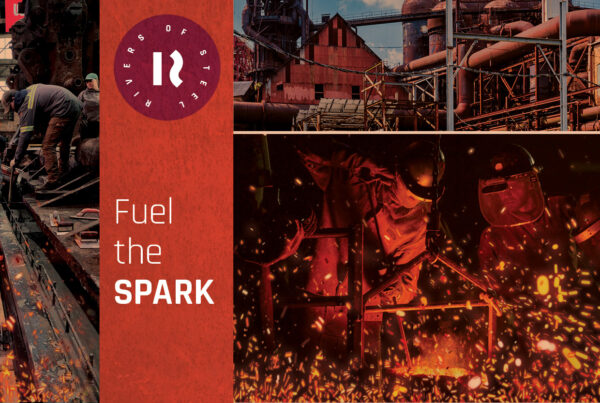

The Pusher Engine, a highlight on the Industrial Tour of the Carrie Blast Furnaces. Photo by Kevin Scanlon.

Restoring the Pusher Engine—A Volunteer Story

In our recent story on The Historic Preservation of the Carrie Blast Furnaces, we mentioned that much of the early cleanup onsite was done with the help of volunteers. Keith Clouse and Kevin Scanlon are two individuals who have donated their time and expertise with us in many ways, including acting as tour guides, since that time. In recent years, they have led the efforts at Carrie to restore the Pusher Engine, a General Electric 80-ton locomotive . . .

A Familiar Feature, the Pusher Engine

Over the last decade, several hundred thousand people have taken an Industrial Tour of the Carrie Blast Furnaces. The tour follows the iron-making process, sharing behind-the-scenes knowledge of the operations along with stories about the workers and their culture. The #101 Pusher Engine, also known as a switcher engine, is just one of the many assets found within the site that had been left behind at the mill’s closure, an important part of the tour that helps to show how raw materials become iron.

“A vital cog in the movement of raw materials within the Blast Furnace site, the engine served as an intramodal form of transportation,” said Ron Baraff, Rivers of Steel’s director of historic resources and facilities. “It was used to move hopper cars full of iron ore into and out of the stationary car dumper so that they could be unloaded and the ore distributed to the ore yards and blast furnaces.”

Yet for much of that decade of tours, the #101 Pusher Engine sat in disrepair, damaged by the effects of nature and defaced with graffiti—until 2019.

The Pusher Engine as it appeared in the late summer of 2018.

Removing Layers of the Past

Keith Clouse and Kevin Scanlon began volunteering for Rivers of Steel in 2010, but their friendship goes back decades before then. They had bonded over their passion for railroads and the industrial history that goes with them, so volunteering at Carrie was a good fit—and restoring the #101 was the perfect project for them.

“Kevin and I were among the volunteers working to undo almost 30 years of neglect to open the site for visitors,” said Keith Clouse. “Early on, we worked around the car dumper, cutting away the thick foliage, uncovering the 101. Although the idea of restoring her was something we considered, it would have to wait until more pressing work was completed.”

“In the fall of 2019, Ron Baraff and Ryan Henderson [an interpretive specialist for Rivers of Steel] convinced us it was time to move ahead to begin the restoration of #101,” Keith continued. “First, we needed a thorough cleaning of the accumulated debris and leaves; taconite pellets were everywhere inside. Next the big job—remove the rust. The first attempt at sand blasting didn’t work out well. It was going to take more time, but using grinders with abrasive disks proved to be a better choice.”

Kevin Scanlon added: “The restoration stretched over the summers of 2020 and 2021. We stripped it down to bare metal with hand grinders, then had to patch some pretty large rust holes in the corners of the car body. There are reservoirs in each corner that hold moisture and ended up eating away the metal. We also had to contend with a yellowjackets’ nest inside one end. They did not like us fussing around their home and let us know about it.”

Keith Clouse and Kevin Scanlon pose with #101 when it was in red primer.

With the patch welding completed, a layer of primer was applied, stabilizing the engine body. By the fall of 2020, additional repairs were made to the floorboards inside the cab, and the windows were repaired, securing the interior before winter’s arrival.

Keith Clouse painting the base layers of color over the primer. Photo by Kevin Scanlon.

Painting the Pusher Engine

While removing the layers of old paint, the crew uncovered several paint schemes from over the years. However, with input from Ron Baraff and Ryan Henderson, the decision was made to use an orange and black design from the 1960s.

While Kevin Scanlon and Keith Clouse led the project (and did much of the hands-on work), they were not alone in their efforts. Rivers of Steel’s volunteer crew assisted with applying the final coats of paint in 2021. The team included volunteers Tommy Britt, Mike Dietrich, Alex Hiniker, Grant Kenny, Mike Lickert, Laura Lovett, and Shelley Parkerson.

Just a few details remain to complete the project. A sign with the U.S.S. Steel Homestead Works logo will be added to the sides of the cab, along with signage that reads “REMOTE CONTROL,” which is to be hung on both ends of the engine.

“Recognizing that it was an important asset to the story of iron production at the Carrie Blast Furnaces and being great lovers of railroad transportation, Keith, Kevin, and the entire volunteer crew embraced the challenge of restoring and preserving this important piece of history,” said Ron Baraff.

The volunteer crew helping to complete the paintwork in November of 2021. Photo by Kevin Scanlon.

The Impact of Volunteers

The efforts of the volunteers who participated in this project have allowed Rivers of Steel to use the engine as an educational tool and attraction at the site. This and other labors of love by our volunteers allow us to continue to enlarge our narrative, engage the public, and enhance our interpretation of our region’s industrial legacy.

“Without their dedication and enthusiasm, we would not be where we are as an organization, nor would the site be the attraction that it has become,” said Ron Baraff. “From landscape management to historic preservation projects, the Carrie crew has made an immeasurable impact on the National Historic Landmark site.”

“Their efforts have greatly aided our work and made our jobs more enjoyable,” Ron continued. “While every volunteer comes into the organization with different skill sets and perspectives, they all bring a great love of history and a dedicated commitment to excellence with them. They are our friends, our supporters, and among our greatest assets. Their work is historic preservation at its grassroots, hands-on finest!”

The Pusher Engine with the car dumper and ore bridge in the immediate background.

Photo by Adam Piscitelli / Primetime Shots.

Interested in reading more? Check out our recent story on The Historic Preservation of the Carrie Blast Furnaces.