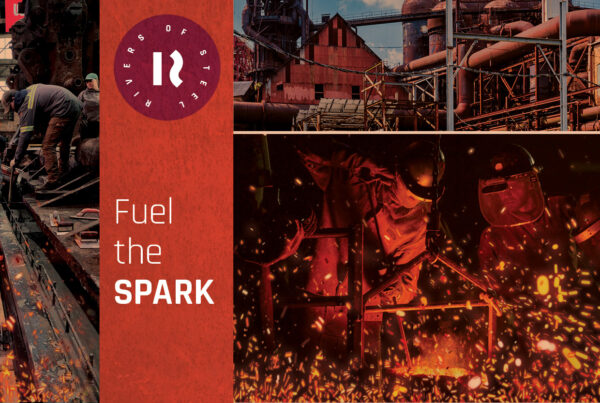

Trainees Kiersten Lapen and Nathan Swiech pictured with Ron Baraff, Director of Historic Resources and Facilities

First Cohort in the Traditional Trades Workforce Development Program Begins

Rivers of Steel is proud to announce the launch of its first cohort in the Traditional Trades Workforce Development Program, designed to train and empower individuals seeking careers in fields such as welding, carpentry, and masonry. This program is the first of its kind to be launched as a paid training opportunity, set against the backdrop of the historic Carrie Furnaces. With a robust curriculum focusing on essential skills in welding, carpentry, and masonry—framed within the tenets of historic restoration and preservation—participants will attain industry-recognized certifications that uniquely position them for entry into the workforce, trade union membership, or continued education in the trades.

Last spring, we introduced this new vision for workforce development as a pillar of the Partners for Creative Economy initiative to unite, uplift, and empower communities throughout the Rivers of Steel National Heritage Area. Evolving out of a workforce training pilot that focused on the restoration of the 48-Inch Universal Plate Mill, Rivers of Steel welcomed its first official cohort at the start of May 2025.

The inaugural cohort welcomes two enthusiastic trainees, Kiersten Lapen and Nathan Swiech. Lapen came to the cohort after graduating from the Introduction to Construction Trades Program at the Pittsburgh Gateways Corporation. Following that program, she worked in the plasterers union but wanted to pursue additional training in a variety of trades. The opportunity to gain experience across multiple trades made the program particularly appealing. When asked about her involvement in the program, Lapen said, “I’m so excited to be involved in a piece of history as impactful as Carrie Furnaces. To have the opportunity to learn the trades, be exposed to labor history, to connect with individuals with diverse backgrounds—from metalworking to machinery to the archives at Rivers of Steel—it all amounts to a uniquely well-rounded and fascinating program. I’m proud to be a part of it!“

- Kiersten Lapen

- Nathan Swiech

Nathan Swiech comes to the program after working for over thirteen years in the culinary industry as a cook. While he enjoyed his time in the kitchen, he was eager to find another career path. His love of history, particularly local history, made this opportunity even more exciting for him. When asked what he likes most about the program, Nathan said, “Growing up I was always told, remember where you come from, and this program gives me the opportunity to preserve where I come from—I’m not going to lie, it’s kind of magical! The second you step onto the grounds at Carrie Furnaces, you can feel the souls of the people who were there and the legacy they left.”

Trainees Lapen and Swiech begin shop preparations ahead of their work on 48 inch Universal Plate Mill and technical skills modules.

Over the coming months, participants in the program will work alongside Rivers of Steel staff to execute projects in multiple trades, positioning them for work as millwrights, welders, masons, and carpenters. Participants will have the opportunity to complete NIMS certifications, welding D1.1 certification, OSHA safety certifications, and NCCER certifications in carpentry. Additionally, they will participate in concrete projects, machining projects, and small motor repair to aid in artifact restoration and preservation. Skillset development and related certifications create opportunities for work in historic restoration and regional industry.

In a time of computers, robotics, and technology, it may be pondered: why historic trades? Historic trades education covers a vast array of skills including those broadly recognized as essential to the field such as tool mastery, measuring systems, craftsmanship techniques, and material knowledge. However, a career in the historic trades also requires ingenuity, problem solving, and adaptability. Working with irregular materials or creating parts that are no longer manufactured requires professional agility—a skill transferable to any industry. Understanding the roots of how things were made previously often inspires innovation, such as historic joinery techniques that influence modern design and sustainable architecture.

Progress continues on the restoration of the 48 inch Universal Plate Mill following completion of the concrete footers during the winter of 2025. Workforce trainees will support the project team during final assembly and fabrication of the mill’s components.

A pilot program in the summer of 2023, funded by the Department of Conservation and Natural Resources, allowed Rivers of Steel to train two apprentices, Malayna Arambula and Derek Stein, to begin learning about the work of historic preservation from the ground up. This pilot laid the initial groundwork for the workforce development program that exists today and offered these trainees the chance to get their hands dirty helping to restore the 48-Inch Universal Plate Mill, identified by the Smithsonian Institution as the last mill of its kind in the world. Arambula and Stein developed an array of new skills in the trades while preparing the mill for reassembly as the centerpiece for the Rivers of Steel Visitors Center at Carrie Furnaces. Coming full circle, both Arambula and Stein have since joined Rivers of Steel as full-time staff, bringing the experience learned during the pilot phase of the workforce program to support the future of the organization.

Derek Stein is now one of Rivers of Steel’s newest employees, joining the organization in April 2024 as the organization’s first Workforce Instructor. Beginning his career as a welder, Derek started work in custom fabrication and historic restoration before becoming an instructor in multiple subject areas including mathematics, English, and, of course, historic trades. Additionally, he is currently completing a four-year machining apprenticeship through the National Tooling and Machining Association. Beyond his breadth of experience, Derek brings a sincere enthusiasm and passion for the historic trades to the program every day.

Derek Stein, Workforce Instructor at Rivers of Steel

When asked what excited him most about being the instructor, he said, “I’m so excited to be working with people who are new to the trades, people who have an interest in getting exposed to these skills that are so integral to what we experience around us. So many times, people are just mystified by how things get done, but I love when people have the same urge I did—to learn how things work. So to help bridge the gap from mystification to understanding, that’s what I’m most excited about.”

Derek is joined by Samantha Swartz, the first Director of Historic Preservation Workforce Development at Rivers of Steel, who has led curriculum development and implementation of the program. With over fifteen years of workforce development experience across various industries, Sam has been able to establish registered apprenticeships with the Department of Labor and envisions the same for the workforce program at Rivers of Steel. She is thrilled to be working in a trades program and contributing both to the storied history of the organization, as well as building a program that supports the region’s workforce ecosystem. She feels, “When you are training people in historic trades that are connected to the restoration and preservation projects like those with Rivers of Steel, these individuals become a part of that legacy. Contributing to that historic preservation and helping people find career pathways is an incredible intersection for workforce development.”

Under the supervision of Workforce Instructor Derek Stein, Director of Facilities Operations Adam Taylor, and Project Manager Rick Rowlands, the new trainees will continue work on the 48-Inch Universal Plate Mill started by the Carrie Furnaces Maintenance team as well as the participants of the original pilot program. After completing some initial welding instruction and assessment, the new cohort will be integrated into the full restoration of the mill, helping to reassemble and permanently preserve this incredibly unique piece of America’s industrial legacy for future generations.