Rivers of Steel Heritage Corporation—managers of the Rivers of Steel National Heritage Area—is seeking a Senior Director of Events and Tourism.

SENIOR DIRECTOR OF EVENTS AND TOURISM

As a member of the senior leadership team, the Senior Director of Events & Tourism manages the planning and successful execution of all operations pertaining to Event and Facility Rentals and our client’s Tourism and Education departments. Reporting directly to the President & CEO, this position manages a team of three, including the Director of Education and the Manager of Tourism. This is a hybrid position located in Pittsburgh, PA.

POSITION DESCRIPTION

This role is responsible for leading the team charged with growing Tourism and Events to establish:

- Our client as the global destination for steel industry heritage and Carrie Furnaces as the Gateway to the Monongahela Valley

The team’s work includes:

- Amplifying National and State Heritage and receptive tourism programs

- Expanding the brand and access to our client as the “Gateway to the Mon Valley” with dynamic tours and events that celebrate Southwestern Pennsylvania’s cultural heritage of grit and innovation, catering to local, regional, national, and global audiences

- Establishing strategies to increase earned revenue and deliver economic value for communities throughout the National Heritage Area

- Educating the next generation of students about the social, cultural, metals arts, workforce development, and environmental science impacts and opportunities of the four heritage sites

This critical work ensures consistent, high-quality experiences through:

- Keystone annual events: visible events drawing thousands of guests to our client each year

- Rentals: weddings; reunions; theatre; arts performances; and filming for television, movies, and advertising, among others.

- Tourism: receptive bus tours, National and State Heritage areas, and others and a series of themed tours for the public, corporate events, universities, and global historic organizations, among others.

- Education: K-12 environmental science classes, metal arts and graffiti experiences, and school history programming.

- Volunteerism: creating welcoming, meaningful experiences for volunteers, managing recruitment, training, scheduling, and engagement.

Essential Functions:

Success in this role requires team leadership to meet the multi-faceted, fast-paced dimensions of the position.

- This leader manages the administration and logistics of facility rentals, festivals and events, and tours operated by our client and partner organizations at our four historic sites.

- Working closely with our marketing team, facility managers, part-time staff and volunteers, the Senior Director of Events & Tourism will:

- Create and implement strategies to drive visitor and student engagement and ensure exceptional experiences

- Oversee the promotion, planning, and execution of receptive tours as well as sponsored tours across a wide variety of themes and interests.

- Ensure the team delivers a consistent quality visitor experience

- Lead sales, oversee preparation, and set-up facilities for rentals, events, and education programs to ensure all obligations are met with a mind toward safety and hospitality, and that all visitors and staff follow the Code of Conduct agreement.

- Develop and manage annual budget and establish earned revenue goals.

- Monitor volume, sales, revenue, and expenses.

- Recruit, train, schedule, and supervise staff and volunteers across all four historic sites.

Other Responsibilities

-

- Manage data input and tracking in software systems.

- Attend regular leadership, staff and other meetings as required.

- Lead business operations projects at the request of the CEO.

- Collaborate with marketing, development, and historic preservation departments.

- Support the President & CEO in presenting matters relevant to the Board and/or its committees.

- Work closely with the Controller on all financial matters, including managing and balance cash drawers for sales at keystone events and other applicable event rentals.

Requirements

Required Experience & Skills

Success in this position typically requires:

- Bachelor’s Degree (or equivalent experience) in Hospitality and/or Heritage site or related fields.

- Four or more years of relevant experience is preferred, including event management and tourism–ideally with both for-profits and non-profits.

- Knowledge of, and ability to negotiate, complex contractual documents and relationships.

- Demonstrated leadership and managerial capacity, including objectivity and staff engagement.

- A customer-centered work mentality with strong interpersonal, written, and communication skills.

- Technical skills including database management, Microsoft Office & on-line meeting tools; willingness to learn new tools to ensure efficiency. Familiarity with Blackbaud-Altru CRM is a significant bonus.

- Strong attention to detail and accuracy and the ability to manage multiple responsibilities and prioritize work is important.

Values & Competencies

The successful candidate will possess a strong commitment to our organizational values. A deep connection to the community and its history and evolution is strongly desired. Our work, coupled with this commitment and connection, will be reinforced by the following attributes and competencies:

- Approachable – relates well to all people, internally and externally; builds constructive and effective relationships; uses diplomacy and tact; can diffuse tense situations and communicate complex decisions comfortably.

- Discerning – makes decisions based upon a mixture of analysis, wisdom, experience, and judgment; seeks solutions and suggestions to make and communicate appropriate decisions; perceptive and insightful. Strives for objectivity.

- Collaborative – fosters partnerships and productive working relationships in all circumstances; serves as a bridge between people and ideas, ensuring connection and understanding to achieve shared objectives.

- Effective & Efficient – organizes people and activities; understands how to ensure efficient tasks and workflow; gets the most out of limited resources.

- Transparent & Accountable – values clear communication and confidentiality; obligated and willing to be responsible for decisions, outcomes, and relationships.

Other Expectations & Considerations

The candidate will work a hybrid schedule balanced between our historical locations and our headquarters office in Homestead, PA.

Candidates must:

- Possess a valid Pennsylvania driver’s license and have a reliable vehicle available for work use.

- Clear all applicable Commonwealth of Pennsylvania background checks, including Pennsylvania Child Abuse History (Act 33), Pennsylvania State Police (Act 34), and FBI fingerprinting (Act 114).

- Undertake some physical activity and work including light lifting.

- Work evenings, weekends, and/or holidays, as needed.

- Limited travel is required

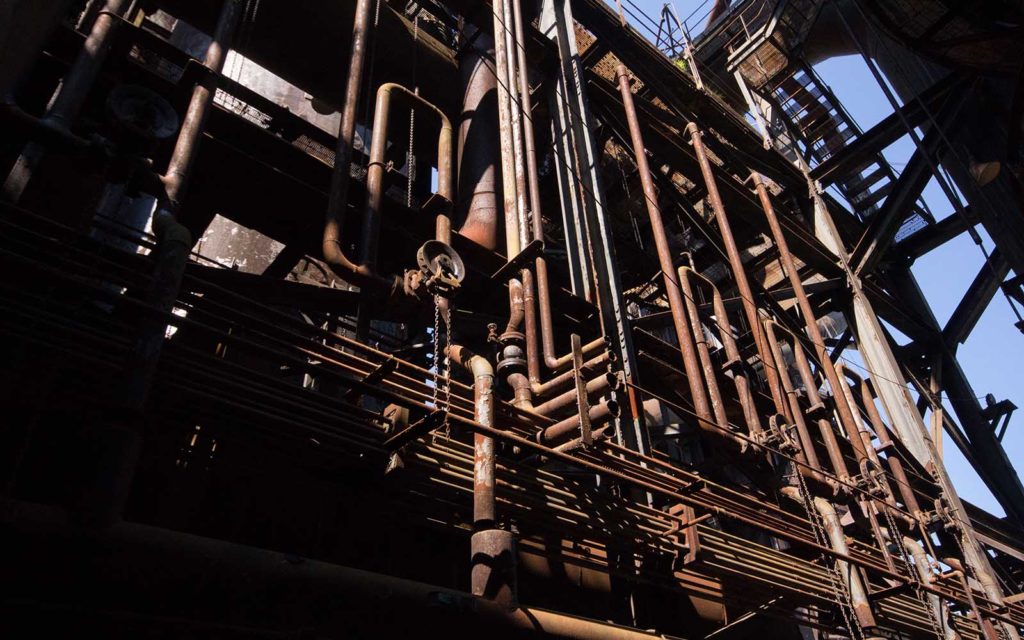

About Rivers of Steel

Founded on the principles of heritage development, community partnership, and a reverence for the region’s natural and shared resources, Rivers of Steel strengthens the economic and cultural fabric of western Pennsylvania by fostering dynamic initiatives and transformative experiences. Rivers of Steel showcases the artistry and innovation of our region’s industrial and cultural heritage through its historical and 21st-century attractions—offering unique experiences via tours, workshops, exhibitions, festivals, and more. Behind the scenes, Rivers of Steel supports economic revitalization, working at the grassroots level to deepen community partnerships, promote heritage tourism, and preserve local recreational and cultural resources for future generations.

Application Process

Please provide a detailed resume and cover letter delineating your relevant experience to Hayley Jameson at hayleyj@hdjassociates.com. Applications will be accepted until the position is filled. Only applicants most closely qualified for the position will be contacted for an interview.

Rivers of Steel is an equal opportunity employer and does not discriminate in hiring, transferring, promoting, terminating, paying, training, benefits, or other actions affecting employees. Rivers of Steel does not make any personnel decisions based on race, color, sex, age, national origin, religion, ancestry, marital status, veteran’s status, non-job related disability or handicap, or other prohibited criteria.

What You’ll Find Beyond the Flames

What You’ll Find Beyond the Flames A First Festival for Rivers of Steel’s New CEO

A First Festival for Rivers of Steel’s New CEO The Festival of Combustion 2025 is made possible thanks to our sponsors:

The Festival of Combustion 2025 is made possible thanks to our sponsors: